In Focus: High-frequency data aids energy conservation

“It is becoming increasingly clear that vessel owners, and possibly the marine industry, should recognise, internalise, and adopt digitalisation techniques if they desire to reach 2030/2050 international emissions goals more easily and in a more sustainable fashion,” says José González, energy conservation manager at Stolt Tankers.

González is responsible for planning and managing energy projects and setting up long-term strategies in energy conservation and is all about prognosis.

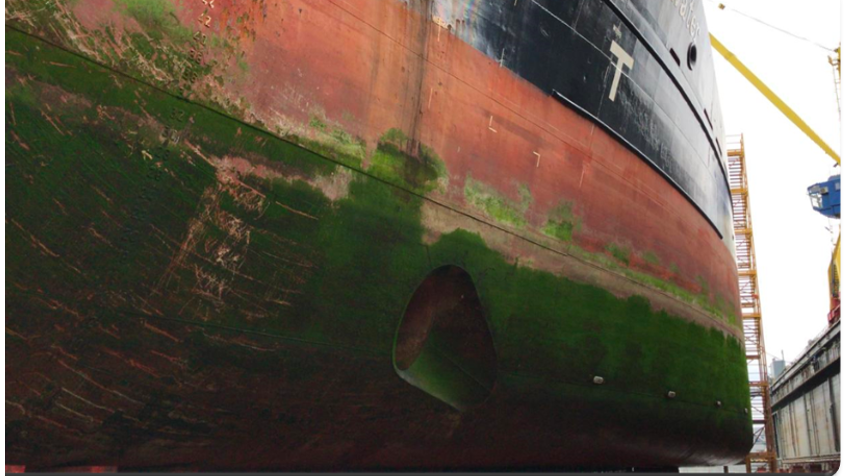

One of the ways to achieve that, he says, is that shipowners should be looking for biofouling prognosis, “allowing shipowners to take timely decisions and to accommodate the inspections/cleanings as per the real needs and the trade mandates.”

González believes that there is a clear link among the utilisation of promising data technologies and reducing biofouling. He says shipping companies should not be hesitant to embrace data tools and aid the myth busting.

“Companies that do so will be able to create more effective designs that meet constantly evolving goals. They’ll be able to manage their vessels in real-time (and create optimal routing schedules), decrease emissions to the environment, increase workplace safety, and increase profitability.

“We have still got a lot of work to do, and there are plenty of aspects to be revisited when it comes to biofouling and ship performance topics, but it represents an initiative to take it seriously,” González says.

The most common way of reporting data in the maritime industry is through the Noon Report. It has been in use for decades to circulate information from ship to shore and from ship/owner to charterer (like vessel coordinates, weather conditions, voyage details, fuel data, cargo specifics). González says it has important drawbacks for biofouling decisions, not least inaccuracy due to inadequate data quality, absence (hard to) run complex analysis due to its low frequency nature, and additional workload created for the crew on board.

Thus, he says, “The evolution of the digital world offers unique tools to the marine industry that may help to ensure that regulations to come, and profitability, are met and maintained.”

Stolt Tankers uses high frequency data

The use of high frequency data collection and predictive modelling made it possible for Stolt Tankers to save $61,000 in fuel costs over a two-month period during the 2023 financial year (once the project was fully implemented the savings have been higher). “We use S-Insight from Storm Geo as a performance tool, but it is not only about the software itself. It encompasses the whole interpretation of the findings and the technical expertise in-house.”

González calculates that 373,000kg of CO2 emissions were not emitted. The high frequency data relating to emissions helped identify ships whose hulls/propellers were being fouled earlier than they would have been spotted with traditional processes (visual inspections).

“Some owners have started using high-frequency auto-logging data collection that might be streamed into prediction models for different applications,” González says.

“The rationale behind high frequency data collection systems is to identify those ships whose performances are not optimal. However, there are some considerations to be considered by shipowners with vessels of varying ages, varying trades and varying degrees of digitisation.

“The ability to perform advanced data analytics on older vessels is limited, these ships are often higher consumers, and often require more attention to maintain optimal operating efficiencies.”

González notes that the reliability of the models can vary. Factors such as data collection type, the huge variety of shipboard equipment and interfaces, the lack of global standards for data format and tagging can make it difficult to properly tailor an accurate business case.

Nevertheless, with the results that Stolt has achieved, he is confident that data can – and will – continue to change biofouling practice.

In the meantime, he says: “It is of paramount importance to banish some misconceptions related to biofouling phenomena that can still be heard in some maritime forums: like biofouling only happens in high seawater temperature areas, the impact of biofilms in ship performance is not decisive, the biofouling issue is just a matter of concern for those ships sailing fast and consuming a lot of fuel on a daily basis. None of that is true; the data speaks for itself.”

In 2023, Stolt Tankers became the first chemical tanker company to apply Graphite Innovations & Technology’s graphene-based propeller coatings to its fleet.

The two companies signed a two-year agreement to apply GIT’s XGIT-PROP graphene-based marine coating to the propellers of 25 Stolt Tankers. XGIT-PROP is said to be an eco-friendly product that reduces marine growth and improves propulsion efficiency while ensuring no harmful toxins or biocides are released into the ocean.