Flexiteek highlights importance of apprentice development

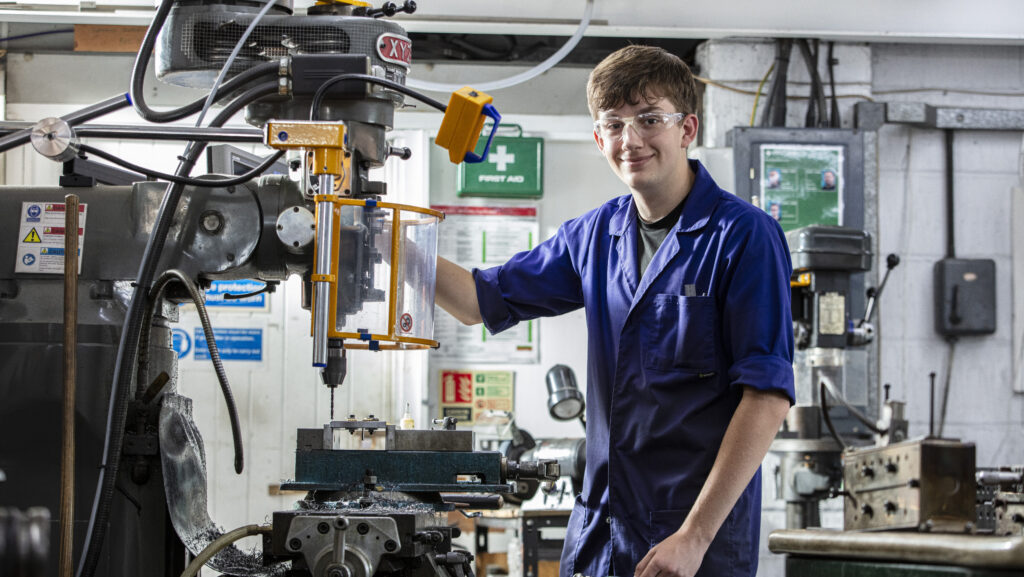

High-performance synthetic decking manufacturer Flexiteek is marking one year of its apprentice Riley Chamberlain’s development within the company, highlighting the importance of such schemes for the wider marine industry.

The four-year Machining Technician Level 3 Apprenticeship, which aims to provide practical training in a manufacturing setting, is being delivered in partnership with Colchester Institute.

Chamberlain joined the firm during the launch of Flexiteek 3, which was unveiled at Metstrade 2024. Over the past year, he has undertaken a range of engineering and manufacturing tasks while building his competence in key areas, including machining techniques and 2D design systems.

“My confidence has improved greatly in operating machinery and the 2D design systems compared to where I started,” says Chamberlain.

Chamberlain has completed his apprenticeship workbooks and passed all required health and safety assessments. He now produces clamp rings on a lathe and replicates key tools, supporting tooling development for Flexiteek 3.

“Riley has progressed and learnt so much from when he started working for Flexiteek,” adds Steve Waldie, engineering and product development manager at Flexiteek.

Apprenticeships remain a critical pathway for addressing skills shortages in the engineering sector. They combine academic learning with real-world application, offering young professionals structured routes into technical roles.

“Apprenticeships are not just about training — they’re a strategic investment in our future,” says group CEO Adam Ramsden. “Riley has brought fresh thinking, energy, and an eagerness to learn that has already made a real difference in our business.”

Looking ahead, Chamberlain will begin work in 2D CAD design, CNC milling and engineering mathematics and will train in CNC programming and CAD/CAM systems. “I am looking forward to bettering my skills in 2D design work for the tooling as well as the process to help to make a better product,” he adds.

In a statement, Flexiteek highlights that apprenticeship schemes like this not only support individual career growth but also “strengthen the wider industry by closing skills gaps and building sustainable talent pipelines.”

In 2023, the manufacturer of engineered synthetic decking and marine products moved to a new state-of-the-art facility in Fagersta, Sweden, after more than 23 years in its original production facility.

Read more about marine apprenticeships in the boatbuilding sector

Leave a Reply