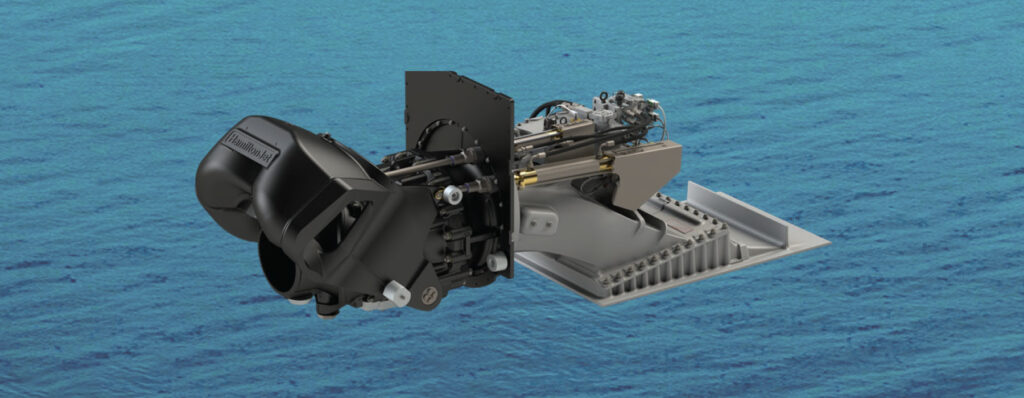

Kiwi company unveils new waterjet technology

New Zealand-based HamiltonJet, a leader in waterjet technology, is unveiling a new range of high-efficiency waterjets, starting with the LTX36 model. Optimised for medium and low speed operation, HamiltonJet says it has produced the first waterjet to rival the energy efficiency and bollard pull of the best propeller-based systems between zero and 30 knots.

The company says waterjets have always been the most efficient choice for going fast but HamiltonJet CEO Ben Reed explains not everyone wants to go fast.

“Our customers’ needs are changing, and so is our environment. We understand that operators not only want to reduce their impact on the environment and lower their energy costs, but also maximise efficiency,” says Reed.

Some operators achieve this by operating at lower speeds, while others rely on the electrification of the driveline rather than continuing to rely on fossil fuels.

“LTX36 is a game changer. It delivers incredible energy efficiency at low speeds. Customers can enjoy all the benefits they’ve come to expect from HamiltonJet waterjets – shallow draft, manoeuvrability, and safety of people and marine life in the water – allowing you to do more without compromises,” Reed says.

To produce the most efficient propulsion system on the market for low to medium speed applications, HamiltonJet says it looked to nature for inspiration.

“The moon jellyfish expends far less energy than any other swimming animal, evolving over a millennium to become a marvel of jet-propelled efficiency. Thankfully, we didn’t take a millennium to design the LTX36. Like its inspiration, the LTX36 uses a large nozzle, lower input energy, lower jet velocity, and lightweight structure to achieve its goals. So, whether you’re looking to optimise your entire enterprise or simply gain incremental benefits in manoeuvring, loitering, and transit – efficiency of propulsion is key,” says Ben.

LTX36 waterjet technology:

- Ultra-efficient mixed-flow pump design

- Compact in-board footprint

- Narrow width for compact driveline spacing

- Direct drive capability

- Refined corrosion protection