The hydrogen boat you’re not meant to notice: Inside the TYKUN H1

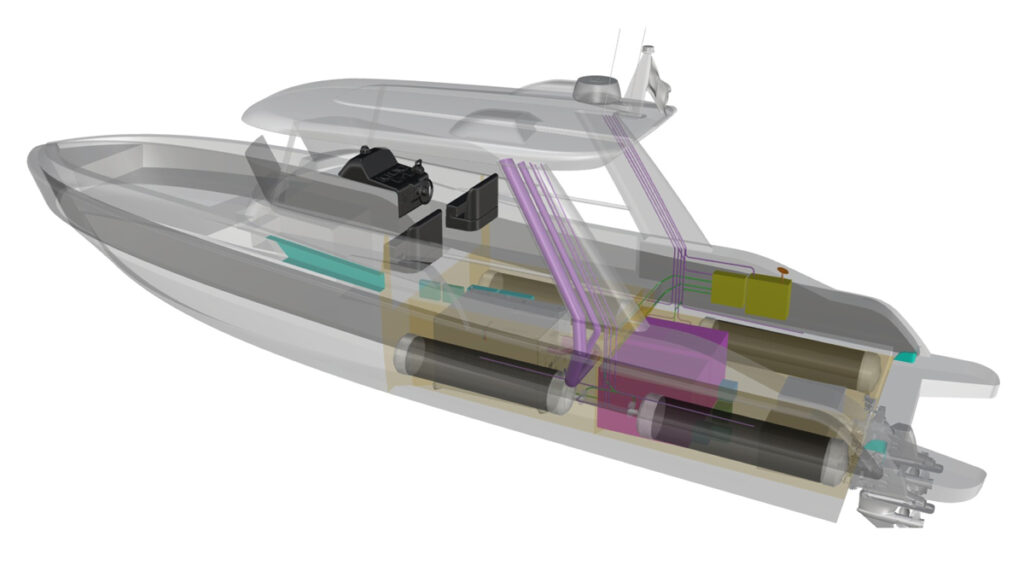

Hydrogen propulsion sometimes announces itself through complex layouts and visible technical compromises. With the TYKUN H1, MED Group set out to do the opposite: to create a high-performance tender where the presence of hydrogen is almost invisible, delivering clean electric boating without changing how the boat looks, feels, or operates.

“The goal was to design a layout so that you can’t tell it’s a hydrogen boat,” says Ugo Casadio, chief technical officer at MED Group.

Hot from winning the Tenders/Water Toys category at the Monaco Yacht Show’s inaugural Blue Wake Awards in September 2025, the model has been fully engineered and is ready to build for customers who want to enjoy clean, green electric boating at speeds up to 35 knots, with extended range and built-in redundancy for flexibility, says an official statement.

From America’s Cup technology to customer-ready boats

At 12 metres, H1 draws on the expertise of TESYA Group, which developed the hydrogen propulsion for the America’s Cup chase boats used during the 37th America’s Cup in Barcelona. H1 also taps into the hydrogen infrastructure of NatPower H.

The MED Group team and designer Tommaso Spadolini have worked to integrate the hydrogen system into the hull which draws on MED Group’s previous naval architecture and the customisable flexibility of aluminium.

Now it’s got a boat with an advanced yet simplified propulsion system and the ability to accommodate high-spec dayboat and superyacht client requirements.

“The TYKUN H1 project began with a key challenge – to produce a hydrogen tender that was usable and manageable for a customer,” says Casadio. “We were lucky enough to make the acquaintance of the TESYA Group team, who had just come from producing the chase boats used in the last America’s Cup. Key to the H1 project was to translate this experience into a boat that more mainstream customers could enjoy.”

Electric propulsion with hydrogen range extension

H1’s core target specs were to use hydrogen in a manageable tender that would offer clients autonomy for a day with a range of 50 to 60 nautical miles, a maximum speed up to 35 knots, and a cruise speed of around 20 knots.

“The goal was to introduce a boat that was easy to operate and manage, while also delivering the style and customisation of our TYKUN dayboats and superyacht tenders.”

In essence, the TYKUN H1 is an electric boat, with a battery bank powering electric motors. A fuel cell, powered by gaseous hydrogen, serves as a range extender by recharging the batteries and extending the vessel’s range to 60 nautical miles. The system also includes a regular shorepower connector for fast charging, meaning the H1 can be used as a high-performance electric tender even if there’s limited access to hydrogen.

Infrastructure support through NatPower H

NatPower H, which offers hydrogen fuelling at key ports and marinas and also provides mobile services, has partnered on the project.

“At NatPower H, we are creating the global network infrastructure for ports and marinas, with 40 refuelling points already operational for hydrogen,” says NatPower H’s Marco Vassallo. “We work with hydrogen in gaseous form, and we have completed refuelling operations in Monaco, France, Italy, and on the Italian lakes, for example.”

The job of simplifying the hydrogen system fell to the Tesya team.

“Building two hydrogen foiling vessels for the last America’s Cup was a good test for us because the boat performance requested was extremely high,” says Vittorio Maccone, sales engineer at Tesya Group. “We gained a lot of experience, collected data and built knowledge that enabled us to re-engineer the system to create something much more user-friendly. The work we did with MED Group on the H1 was all about building a hydrogen boat that could be used by everyone.”

Safety, simplification and system approval

Simplification of the systems has been key to making the H1 easy to use and to operate, and to deliver peace of mind for owners through the application of rigid quality standards and a focus on ultimate safety.

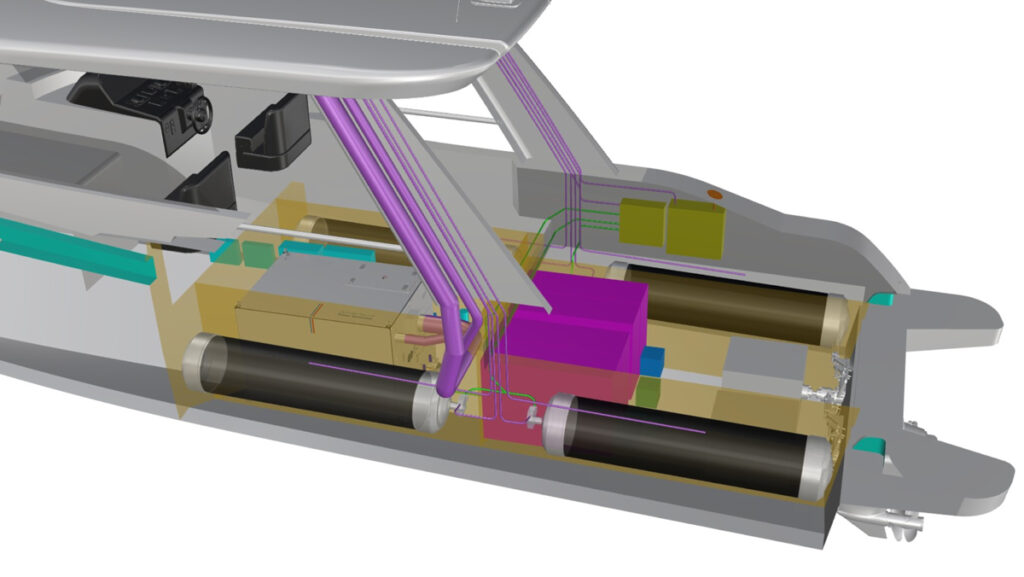

Four concealed tanks hold around 32kg of hydrogen at a pressure of 350 bar. A simplified piping system delivers the hydrogen to the fuel cell which converts it into electricity with the only emission being pure water.

The power generated by the fuel cell is used to recharge the battery bank.

“It’s like having an electric boat with the charger always plugged in,” Maccone asserts. “It means we can overcome the challenges that impact all electric boats – range and recharging time – as refuelling the hydrogen tanks takes less than three minutes.”

The system uses equipment that has been Type Approved by leading classification societies. “Type Approval includes the tanks, the fuel cell, and the battery bank,” Maccone confirms. “We paid close attention to safety, including where the hydrogen is stored to enable both natural and forced ventilation, which means the H1 always has a safe operational profile.”

Ready for build and series production

For the design of the TYKUN H1, the team worked hard to minimise the aesthetic impact of adding hydrogen tanks.

“Aside from the ventilated tank spaces we also had to incorporate compartments for the battery bank and the fuel cell, but we achieved that while still, for example, being able to retain bow storage for the customer,” says Casadio.

“We retained the design cues of the TYKUN range with only a 10-centimetre raising of the deck, also allowing for the safety aspects by, for example, incorporating the ventilation intakes in the T-top supports.”

Now the TYKUN H1 is fully engineered, the team is ready to begin construction with an estimated timeframe of eight to ten months for the build of the first prototype. Once series production begins, the delivery time for a new H1 is estimated at between six and eight months, with possible variations based on the level of customisation required.