Bas Eerden, global sales manager for Yanmar Marine, on the growth of retrofit

Yanmar Marine International (YMI) has embraced the retrofit market. It’s making the most of brand-loyal customers who are avoiding hull modifications. Here, YMI’s Bas Eerden sits down with MIN to discuss the retrofit side of the business and how emission regulations affect global roll-outs.

“While we do not disclose specific figures, retrofit represents a strategically important segment for Yanmar. It plays a significant role alongside our new engine sales. We’ve noticed that retrofit customers are very loyal to the Yanmar brand,” says Eerden.

Within the company, most propulsion and control systems can be retrofitted or upgraded to meet current performance and regulatory standards.

“Retrofitting allows owners to significantly extend the life of their vessels without requiring hull modifications, thereby reducing cost and complexity when repowering,” says Eerden. “Retrofit solutions are typically chosen by customers whose engines have reached the end of their operational life and wish to repower their vessels without needing hull modifications.

“Most of our engines can be retrofitted on existing engine beds. Additionally, Selective Catalytic Reduction (SCR) retrofits are commonly adopted by owners operating in emission-regulated zones. This includes mostly commercial vessels, but also leisure boats over 24 metres in length.”

Eerden explains that YMI offers retrofit propulsion packages designed to fit seamlessly into the footprint of previous Yanmar engines and other brands.

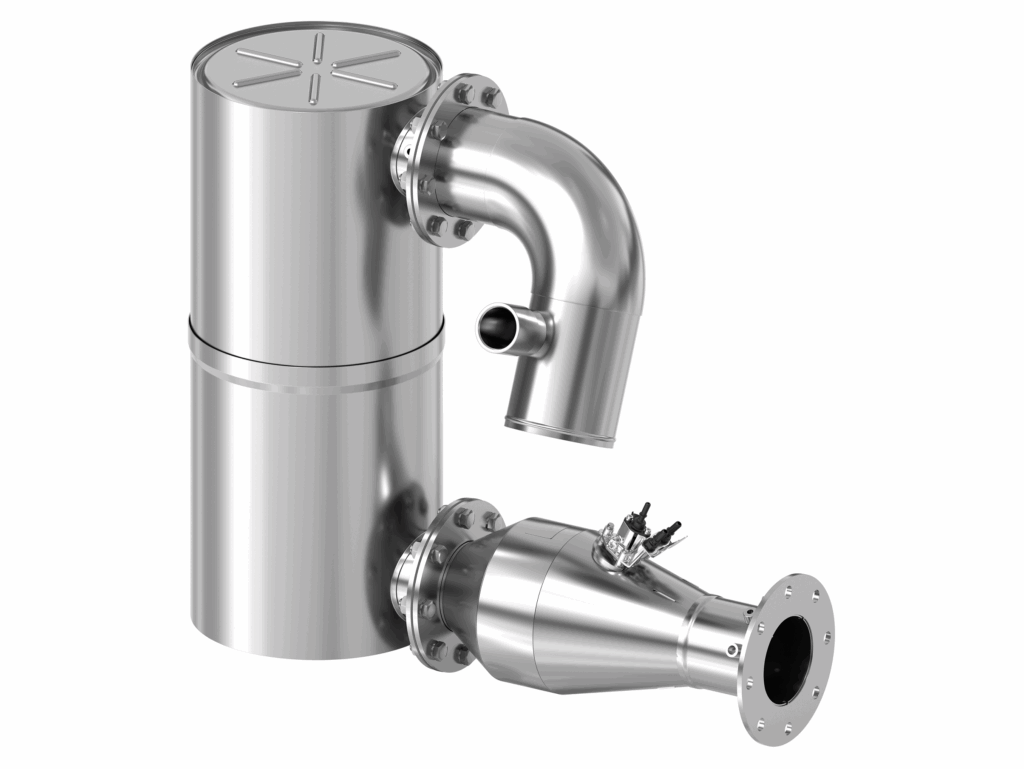

The company’s recently introduced a new Selective Catalytic Reduction (SCR) system. That reduces NOx emissions for power boats from 40-50ft and larger sailboats by up to 90 per cent. This is especially important for commercial boats operating in Emission Control Areas, which are required to adhere to the International Maritime Organization’s (IMO) Tier III strict emission standards.

As such, SCR will not receive a global market rollout, but rather one focused on regions where the system is applicable and where compliance is compulsory.

“However, we anticipate that more areas and countries will adopt similar emission requirements in the future. The SCR system (pictured left) is primarily targeted at commercial vessels and leisure boats over 24 metres, in accordance with International Maritime Organization’s (IMO) Tier III emission standards in Emission Control Areas,” reiterates Eerden.

SCR’s key design feature is its weight and size, which are smaller than those of competitors.

“This system demonstrates our group-wide commitment to reducing the environmental impact of our propulsion solutions and aligns with Yanmar’s 2050 Green Challenge. The Yanmar Green Challenge also reflects our broader mission, not only to offer sustainable products but also to manufacture them in a way that ultimately results in zero environmental impact,” says Eerden.

He says SCR is particularly well-suited for the retrofit market because it fits exactly within the footprint of previous engine generations. “This makes installation straightforward, eliminates the need for structural modifications, and keeps overall costs down. It’s much smaller than other SCR systems on the market and weighs only 86 kg, which also makes retrofitting easier.

“For SCR systems, retrofitting ensures compliance with emission regulations and delivers clear environmental benefits.”

Yanmar has other retrofit innovations.

For smaller engines, YMI has developed an electric solution, the SDe Electric Saildrive, which is compatible with the mounting footprint of the last three generations of Yanmar diesel engines. He says that makes it an ideal and sustainable replacement option.

“One of the standout innovations is the new SDe Electric Saildrive,” says Eerden. That’s a fully electric, sustainable propulsion system that offers a direct drop-in replacement for combustion sail drives.

“It provides an easy transition to emission-free sailing. It utilises a ‘plug and play’ platform for easy installation, with no hull modification needed and effortlessly integrates into existing footprints as a drop-in replacement for combustion engines. The E-Saildrive also has an integrated gear, motor, motor controller, and cooling system, which further eases the repowering process to 100 per cent electric.”

Additionally, Yanmar’s advanced control systems can be upgraded during the retrofit, “providing improved performance, efficiency, and integration with modern onboard technologies,” Eerden concludes.