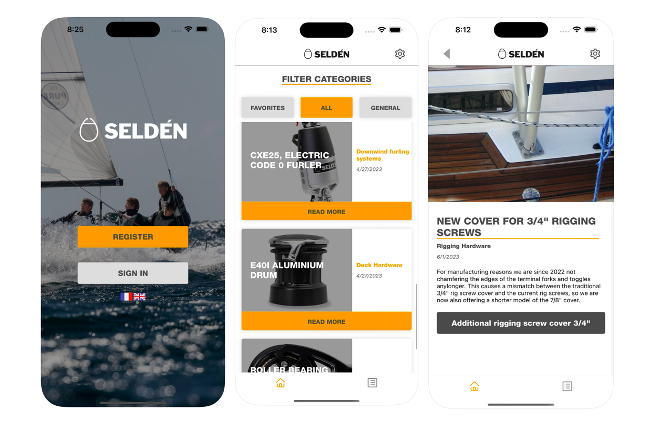

How did Seldén Mast hit upon its integrated system for sail control?

Seldén‘s quest to make sail plans easier to handle started with a simple and practical concept. Matt Sheahan looks at how it quickly developed into a fully integrated solution.

There is clearly nothing new in pushing a button to control a sail. No matter what the size of boat, from 20-footer to supermaxi, powered systems are commonplace across the sport. But what is less common, especially aboard typical family cruisers, is an integrated system for sail handling and control. And as more technology has become available and the knowledge filtered through from the big boat scene, rig and deck gear supplier Selden could see that the time was right for change. The company also believes that there are some practical, down to earth reasons too.

“In general boats are getting bigger, sailors are getting older and companies like ourselves need to be able to provide systems that make larger boats easier to sail with fewer people, it’s as simple as that,” says Selden’s managing director Steve Norbury. “Traditionally, we have supplied electrically powered, headsail furlers and motors for in-mast furling that run on 12 or 24V systems which are wired into the boat’s system and operate as completely independent units. The motors have always been quite big because they’ve been 12 volt motors and the cabling has always been large to avoid current drop.

“But there are more electrical systems on boats nowadays that are standalone systems. So, it struck us that having units that can’t talk to each other doesn’t really make much sense.”

Integration innovation

The overall plan was to create an integrated system where key elements could communicate with each other and where new components could be added at a later date, be it during the build or through the life of the boat. The team started by creating their Synchronised Mainsail Furling (SMF), at the heart of which is Selden’s E40i winch.

“The idea was that it would be fitted on the coach roof so it’s got no gearbox cut out underneath it and it has no handle. All that comes out are two wires. This means that you can fit it to a deck without making any cut outs, which makes it particularly suitable as a replacement winch or as a retrofit, as well as making it easier to incorporate in a new design,” he continues. “In its most basic form it’s an electric halyard winch. But from there, we then developed a system where it could talk to the motor in an electric furling mast, which is what SMF is all about.

“With your outhaul around the E40i winch, when you press the button to unfurl the mainsail, the electric winch pulls in your outhaul and they synchronise together by controlling their speeds. When you take your finger off the button, the system automatically sets your outhaul tension for you.”

Behind the scenes Selbus, the bus system, allows the connectivity and communication but it is also the backbone for what has become a more sophisticated and capable system. One of the key elements is stepping the voltage up from 12/24V to 42V, which allows the use of small motors and smaller gauge cables. Each motor has an MCU (motor control unit) which sends data around the bus to allow the other components to communicate.

“From here we have added our Furlex systems which also run off the same bus. But as well as headsail furling, we have been able to add our GX and CX furlers for asymmetric and code zero sails, all without having to make any major changes on board or install large diameter cabling and big motors.”

The development hasn’t stopped here; hybrid powered systems was the next item on Selden’s development list and a natural progression from the new control network.

The combination of a one button operation for SMF and a manually operated outhaul, the next stage was to include a hydraulic ram in the boom for the outhaul. Once again, using an MCU and connecting it to Selbus means that the mainsail furler can talk directly to the outhaul ram and ensure that the pair work in sync as well as ensuring that the correct outhaul tension is maintained throughout the operation. The result is a one button operation for furling in and one for out.

But to make the process easier, Selden has integrated this operation with the boat’s backstay.

“Furling sails operate best when the mast is straight,” he explains. “So, in an ideal world, when you

are at the dock you’ve released your backstage tension when you unfurl and you keep that backstay tension off until you start sailing. Once you’re underway you tighten the backstay.

“Each time you furl or unfurl, you should ease your backstay tension for the process before pulling it back on, but in reality that’s often hard to do when sailing. But, with a hydraulic backstay that’s connected to Selbus the system will do this automatically.

“So, when you push the unfurl button, it lets your backstay off and when you stop unfurling, it pulls your backstay back on. Then when you furl the entire mainsail away into the cavity, the system knows this and will then ease your backstay.”

But, as Norbury goes on to outline the next phases of development, many of which are still under wraps, there is another piece to add to their puzzle that has been made possible by the development of their E40i winch.

“What we realised was that the E40i winch is great on the coachroof but it isn’t suitable as a primary winch. And yet what’s clear in the 40ft to 60ft market is how many designs now have all their controls led back to two big winches in the cockpit rather than on the coachroof.

“We have an advantage here in that any of our new electric winches can operate as an SMF winch and run off Selbus. This means that any of the furling operations for any of the sails can be carried out from behind the wheel.”

To go from the development of a simple yet innovative electric winch to such a versatile system that can be created step by step is an impressive achievement. And while Selden is tight lipped about what the future holds, once you’ve grasped the concept of the bus and how much information could be coursing through its cables, it starts to become clear that this is just the beginning.

This article was published in Marine Industry News magazine, issue 13.