In Focus: The perspiration and pain behind electric drive development

“People think it’s easy to build an electrical drive system,” says ex-VW group chief strategy officer Michael Jost. He’s gathered a team of ‘believers’ under the banner of eD-TEC to create a high-performance electric drive.

“But it really isn’t as simple as it looks. That has been our experience over the past six months, and in the end that is part of eD-TEC’s added value, because now we know how to deal with and solve the complex problems that arise in a very high-performance electric drive system. The genius simplicity and ease of use for the boatbuilder, and the end user of the Q-Drive, belies the technical complexity and the perspiration behind its development.”

Electric drive development

Jost says he meant to start on-water testing in October 2022, and is already six months behind his own timescale. But with these delays, he says the team has found problems and thus learnt a lot. “That’s the way it is with prototypes and with new technologies,” he says.

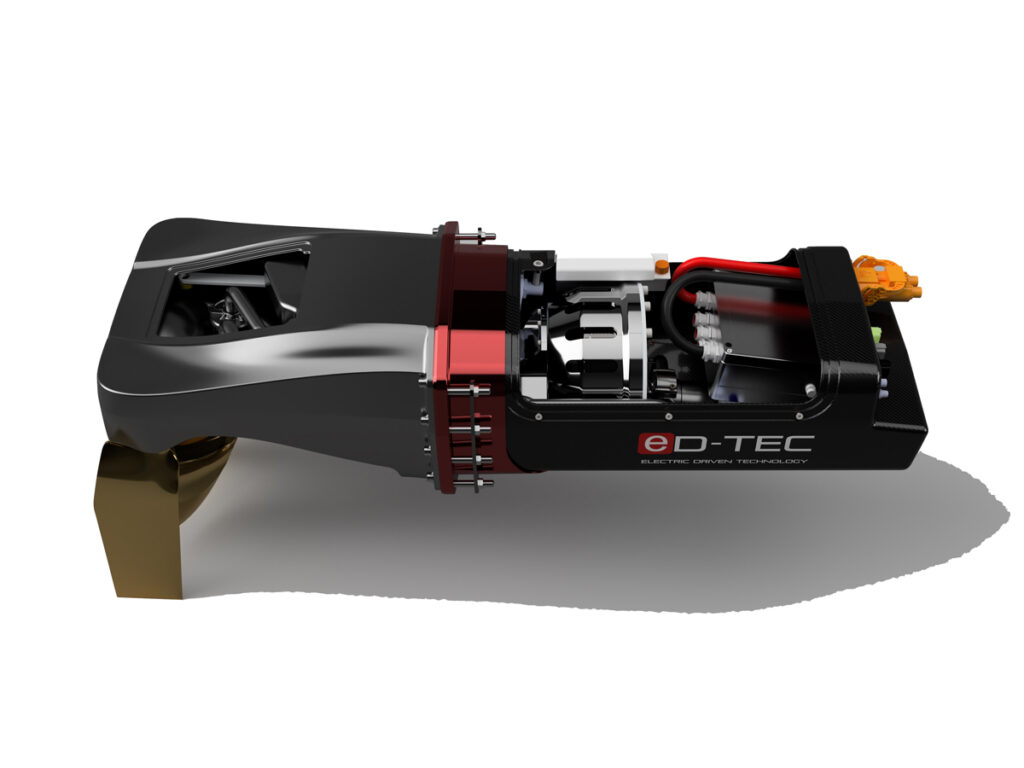

eD-TEC is currently testing its eD-QDrive that comprises a transom-mounted sterndrive unit with surface-piercing propeller that is linked to a high-power electric motor, in turn fed by a battery bank with a high C-rate, and controlled by an advanced hardware and software backbone.

It was unveiled in September 2022, and so far, the team has shown proof-of-concept of its plug-and-play system, and of the drives with initial in-water testing. It’s now gearing up for imminent full-scale, full-speed lake trials of both powercat and monohull test boats, with the drives opened up to 4,000rpm.

“We also fully expect to find new problems because there is no one else developing this type of high-performance, full-electric technology,” Jost says. “There is no one else who can climb the mountain but us.

“The boat is ready, the drives are ready and we are finally ready for the sea. The tech is much more complex than even we realised, but we challenge ourselves and we have fixed problem after problem, because in the real world, between the idea on a sheet of paper and the final successful product, there is a lot of pain.”

Electrical noise challenge

Jost says one of the most persistent challenges was the discovery of high electromagnetic noise from the high-torque motors, which in turn can cause electrical interference in other systems and circuits. This, he says, is one of the challenges in breaking new ground by using far more powerful motors than have yet been implemented in the marine sector.

“How do you avoid electrical noise? It’s not so simple. We’re dealing with a 700-volt system, extremely high torque motors, and more than 100kW continuous supply, although we didn’t expect quite so much electrical noise. So we’ve worked with our electric partners Baumüller to understand the problem and find a solution, and we are implementing that now. We have learnt a lot.”

The team has also experienced the frustration of finding water and oil leaks on the test rig that have very little to do with the drive system itself. It has, however, helped deliver proof of concept for the plug-and-play nature of the eD-QDrive.

“The plug-and-play system works very well, and we know that because we’ve had to unmount and mount the drives several times during installation and problem-solving in this test phase,” says Jost. “We can exchange the drive within an hour, which was a key benchmark when we were developing the system because it makes it super easy for fitting and for maintenance.”

Small steps to integration

The team has also learnt to be a little more patient in its build process for testing.

“At first we integrated everything – the heat exchanger, the inverter, the sensors, noise control, everything – but now we realise that in the real world that’s not so easy,” says Jost. “So now we are creating a much more robust system, and with the electrical noise under control the next big step will be thermal management. We also had some initial issues with a new, dedicated gearbox we developed for the drive, but that’s now been sorted out too.”

Earlier this year, eD-TEC named e.battery systems (EBS) as its new battery technology partner. It expects the first products of the partnership to be ready for market in the second half of 2023.