Solé Advance targets sustainable marine energy with a 76kW fuel cell

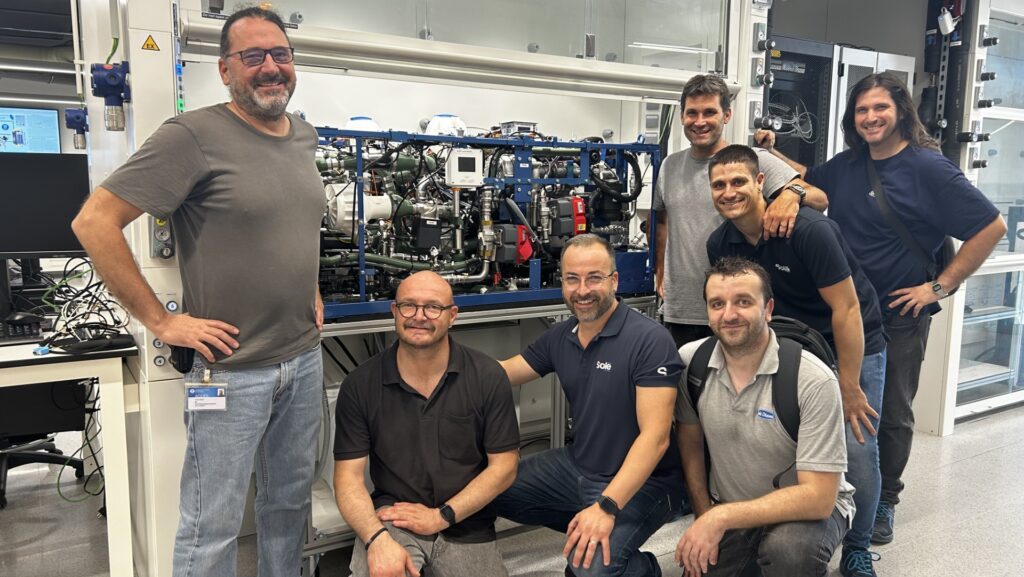

The team (from left) Attila Husar, director of the H2 UPC Lab, with Solé Advance’s engineering team, led by Víctor Miravet. Image courtesy of Solé Advance

The team (from left) Attila Husar, director of the H2 UPC Lab, with Solé Advance’s engineering team, led by Víctor Miravet. Image courtesy of Solé Advance

Solé Advance has revealed a new Proton Exchange Membrane (PEM) hydrogen fuel cell engineered for integration with marine electric and hybrid propulsion systems.

Additionally, used for onboard power generation, the fuel cells have a target output of 76kW and form part of Solé’s broader goals, which include launching high-efficiency product ranges and continuing progress on compatibility with Hydrotreated Vegetable Oil (HVO).

Part of the Spanish firm’s R&D programme, the project is currently undergoing development and validation. While initially focused on marine applications, the initiative also considers industrial use cases.

The fuel cell programme is being developed in collaboration with Applus+ IDIADA and the H2LAB at the University of Catalonia, BarcelonaTech, combining applied engineering, laboratory testing, and academic expertise.

Marieli Solé, CEO of Solé, comments: “This programme is a natural step in our evolution towards next-generation onboard power systems and technological transition: integrating a 76kW hydrogen fuel cell with safety, efficiency and maintenance criteria tailored to real operation on board, in both leisure and workboats. We are a company with strong engineering, design and innovation capability, and this project proves it.”

Solé is focusing on the Balance of Plant (BoP) design, thermal and air management, humidification, purging, power supply, instrumentation and safety. While EKPO, a hydrogen technology supplier, provides the fuel cell stack.

The first integrated prototype has been assembled and validated during initial tests at the university’s laboratory. Its compact design facilitates easier installation in engine rooms and provides access for maintenance services.

Víctor Miravet, director of Engineering and Manufacturing at Solé, says the initial testings have been “encouraging,” and adds: “Our next step is to transfer those results to real operating conditions on a vessel, ensuring optimal cooling, consolidating a robust energy solution within an interconnected onboard energy ecosystem, developing control strategies for the most efficient power management possible, and paying special attention to corrosion resistance.”

Solé Advance will be attending the upcoming Metstrade show, taking place from 18 to 20 November 2025.